〓 LDCR capacitor unique advantages

◇Specially formulated fillers

■ filler and film have a good compatibility, the product in the normal use of 2 years after the capacity change rate of not more than 1.5%.

■ filler and process to ensure product consistency: the use of vacuum sealing process, can accurately determine the product sealing performance, to solve the traditional high-temperature inspection due to the oven temperature, time control relationship caused by poor uniformity, product quality is not accurate The phenomenon

■ At different temperatures, the shrinkage rate is very low, in the -40 ℃ to 85 ℃ are soft, no significant changes in volume.

■ Even if the altitude reaches 4000m, it still maintains excellent heat dissipation and insulation performance.

◇High temperature resistant film

■ high crystallinity: longer molecular chain and less branched, isotactic high, the maximum can withstand 120 ℃ high temperature.

■ lower impurities: ash residue when the detection of less, the lowest breakdown voltage is about 20% higher than the average, so the field strength higher.

◇Professional filter capacitor safety technology

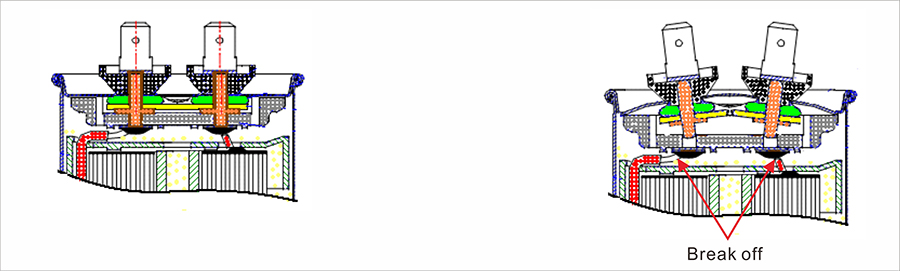

◇Independent unit protection device

This structure is an overpressure separator. When the capacitor breakdown due to overheating, overload or near life, the release of a large amount of gas causes the air pressure in the capacitor shell to rise rapidly and the top cover is bent upwardly. When the expansion exceeds the limit, the internal cable will be quickly separated, the fault components completely cut off. The advantages are as follows:

1, high reliability: shell and cover explosion pressure is the explosion-proof device when the pressure of more than 2 times;

2, high sensitivity: independent unit volume of the traditional design volume of 1/4, the internal pressure will rise rapidly when the failure

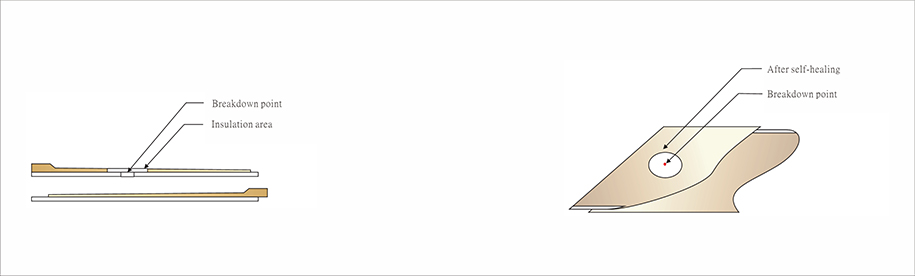

◇Self - healing characteristics

Capacitor metallized film electrode using zinc-aluminum composite technology, the thickness of the electrode is very thin, when the capacitor inside the electrical overload or temperature is too high, there is electrical breakdown phenomenon, the breakdown of the electrode around the ionization, breakdown point to the electrode medium Layer gasification separated, resulting in insulation, the capacitor back to normal working ability.

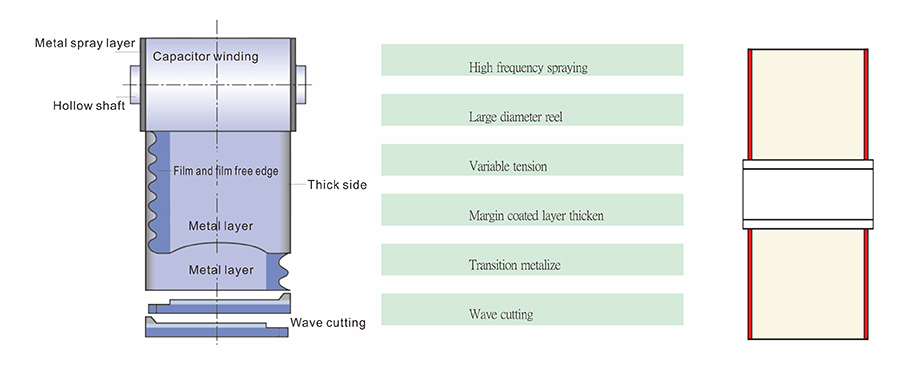

◇Professional filter capacitor manufacturing technology

■ Microscopic analysis of metallized film materials for each capacitor to ensure optimum performance for each capacitor

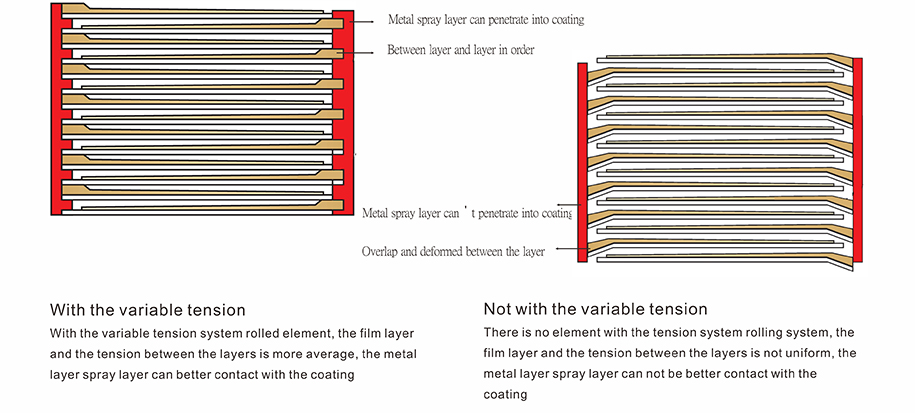

■ With specially developed with the variable tension rolling system, so that the film layer and the tension between the layers more uniform, the metal spray layer can better contact with the coating, thereby enhancing the capacitor surge current capability

■ The use of ripple cutting and edge thickening technology, high-frequency spray treatment of the end face, so that the capacitor has a good over-current capacity

■ The use of gradient zinc-aluminum composite technology, so that the capacitor has a good self-healing ability

■ capacitor with high vacuum heat treatment after the injection of special gas, and then injected into the resin under high vacuum, thereby enhancing the electrical performance of the capacitor

■ Capacitors are tested against current at the factory to ensure the stability of the capacitor

◇Wave Slitting Technology

Reduce the loss, improve the resistance of the capacitor current capability, is to improve the service life of the battery. This technology solves the problem that the contact between the gold layer and the metallized film increases the product loss, increases the contact area between the gold layer and the metallized film, and the shock resistance of the capacitor has been greatly improved.

◇With the variable tension technology

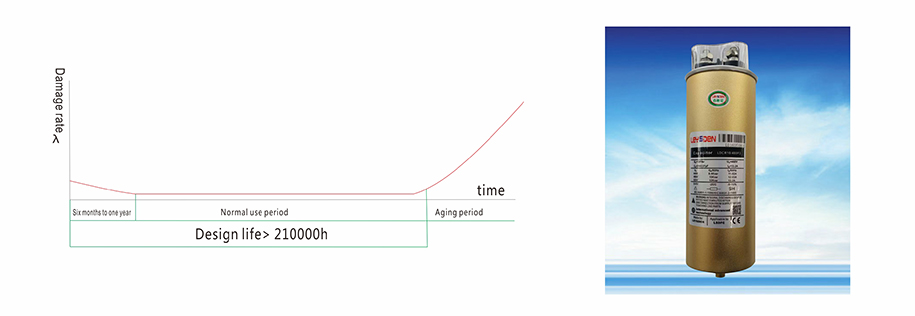

◇Long design life

Factors that affect the life of the capacitor:

Electrical stress: 10% increase in voltage, life reduced by about half

Thermal stress: 10 degrees increase in temperature, life is reduced by about half

Mechanical force: the production of extrusion, collision and so on to the film and its contact parts are damaged

Physical role: the thermal expansion and contraction of the welding process

Chemical effects: acid, organic solvents, moisture and other damage to the capacitor

the measures taken:

For the use of field conditions (power supply system, harmonic conditions, environmental conditions) adhere to the best configuration program, effectively improve the service life;

For the production process, the use of the international advanced level of metallized film and metallized film capacitor production lines, including high vacuum coating unit, high-precision Slitter, ultra-small and medium and low voltage capacitor winding machine, spray machine, automatic welding The production environment in line with the requirements of the EU clean production environment.

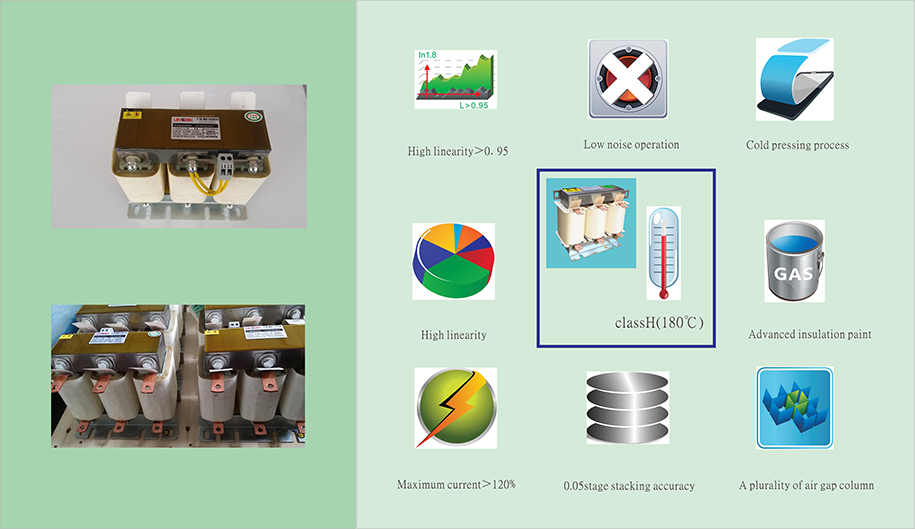

〓 LDTRS Reactor Technical Advantages